Combination of reduction with metallic sodium and adsorption with mesoporous materials for re-refining of used insulating oil via experimental design

Volume 3, Issue 01, Pages 27-40, Mar 2020 *** Field: Industrial Analytical Chemistry

Abstract

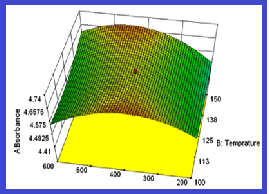

In this study oils used direct influence sodium metallic on oxidation products and refining with the Mesoporous silicate material (MCM-41) and also silicate absorbents was synthesized and functionalized with aluminum salt through wet impreghation method (18wt%Al-MCM-41) (36wt% Al-MCM-41). Physical and structural properties has been investigated by FT-IR, BET,XRD and FESEM methods which shows a succful synthesis of the nano porous material. First step for reducing acid number oil we used direct reaction beetwen sodium metalic and used oil, after this step refining used oil by MCM-41 abosrbent has done. The effect of some parameters such as contact time, temperature and the dosage has been determined and optimized by respons surface method (RSM). The results show that acid number decrease obtained 150 ,60min and 200% of dosage. Optimum condation for absorbent reaction products and new oxidation products by MCM-41 obtained contact time of 120min temperature (120oC) and dosage 200% .

References

A. Hamada, E. Alzubaidy, M. Fayed, Used lubricating oil recycling using hydrocarbon solvents, J. Evnviron. Manage., 74 (2005) 153-159.

D. I. Osman, S. K. Attia, A. R.Taman, Recycling of used engine oil by different solvent, Egyptian J. Petrol., 27 (2018) 221-225.

R. Abro, X. Chen, K. H. Harijan, Z.A. Dhakan, M. Ammar, A comparative study of recycling of used engine oil using extraction by composite solvent, single solvent, and acid treatment methods, Int. Sch. Res. Notices, 2013 ( 2013) 952589.

J.A. Filho, L.G.M.M. Moura, A.C.S. Ramos, Liquid-liquid extraction and adsorption on solid surfaces applied to used lubricant oils recovery, Brazilian j. chem. Eng., 10 (2014) 687-697.

T. Colclough, Role of additive and transition metalin lubricanting oil oxidation, Ind. Eng. Chem. Res. 26 (1987)1888-1895.

K. Satish E. Klaus, L. Duda, Evaluation of liquid phase oxidation products of ester and minaral oil lubricants, Ind. Eng. Chem. Prod, Res. Dev., 23 (1984) 613-619.

S. Bustamante, M. Manana, Dissolved gas analysis equipment for online monitoring of transformer oil: a review, Sensors, 19 (2019) 4057.

Survey of currently available non-Incineration PCB destruction technologies, UNEP Chemical, 2000.

R. Abu-Elella, M.E. Abu, R. Ossman, M. F. Abd-Elfatah, Used motor oil treatment: turning waste oil into valuable products, Int. J. Chem. Biochem. Sci., 7 (2015) 57-67.

MO. Aremu, DO. Araromi, OO. Gbolahan, Regeneration of used lubricating engine oil by solvent extraction process, Int. J. Energy Environ. Res., 3 (2015) 1-12.

M.E. Emetere, Investigations on aerosols transport over micro-and macro-scale settings of west Africa, Environ. Eng. Res. 22 (2017) 75-86.

H. Mensah-Brown, Re-refining and recycling of used lubricating oil: an option for foreign exchange and natural resource conservation in Ghana, J. Eng. Appl. Sci., 10 (2015) 797-801

S.S. Lam, K.K. Liewa, A.A. Jusoh C.T. Chong F.N. Ani, H.A. Chase, Progress in waste oil to sustainable energy, with emphasis on pyrolysis techniques, Renew. Sust. Energ. Rev., 53 (2016) 741–753.

T.E. Oladimeji, J.A. Sonibare, J. A. Omoleye, A.A. Adegbola, H. Okagbue, Data on the treatment of used lubricating oil from two different sources using solvent extraction and adsorption, Data in Brief, 19 (2018 ) 2240–2252.

R. Maceiras, V. Alfonsín, F.J. Morales, Recycling of waste engine oil for diesel production, Waste Manage., 60 (2016) 351-356.

S. Shiung Lam, R. Keey Liewa, A. Jusoh, C.T. Chong, F. Nasir Ani, H.A. Chase, Progress in waste oil to sustainable energy, with emphasis on pyrolysis techniques, Renew. Sust. Energ. Rev., 53 (2016)741–753.

S. Salem, A. Salem, A. A. Babaei. Application of Iranian nano-porous Ca-bentonite for recovery of waste lubricant oil by distillation and adsorption techniques, J. Ind. Eng. Chem., 23 (2015)154–162.

Standard Test Method for Acid and Base Number by color –Indicator Titratian-D947-04.

J.M. Morales, A. Moragues, J.E.l. Haskouri, C. Guillem, J. Latorre, S. Murcia‐Mascarós, A. Beltrán, D. Beltrán, P. Amorós, Low‐Cost synthesis of bimodal mesoporous silica‐based materials by pseudomorphic transformation, Chem. Plus chem., 80 (2015)1014-1028.

R.J. With, R. Luque, V.L. Budarin, J.H. Clark, J.D. Macquarrie, Supported metal nanoparticles on porous materials nethods and applications, Chem. Soc. Rev., 38 (2009) 481-494.

Y.D. Chiang, H.Y. Lian, S.Y. Leo, S.G. Wang, Y. Yamauchi, Controlling particle size and structural properties of mesoporous silica nanoparticles using the Taguchi method, J. Phys. Chem. C, 115 (2011) 13158-65.

P. Swan , R. Walker , B. Wopenka, J. Freeman, Absorption in interplanetary dust particles: evidence for indigenous hydrocarbons and a further link to comet halley, Meteoritics, 22 (1987) 510-511.

A. Zhang , Z. Li ,Y. Shen ,Y. Zhu , Effects of different Ti-doping methods on the structure of pure silica MCM-41 mesoporous materials, Appl. Surf. Sci., 254 (2008) 6298-304.

JOURNAL PUBLISHING AGREEMENT

PLEASE PROVIDE US THE FOLLOWING INFORMATION,

Article entitled:

Corresponding author:

To be published in the journal:

Your Status

I am the sole author of the manuscript

- I am an Iranian government employee.

- I am a European government employee

- I am a Asian government

- None of the above

I am one author signing on behalf of all co-authors of the manuscript

- I am an Iranian government employee.

- I am a European government employee

- I am a Asian government

- None of the above

Please tick the above blanks (as appropriate), review the Journal Publishing Agreement, and then sign and date the document in black ink.

Published Journal Article: the author may share a link to the formal publication through the relevant DOI. Additionally theses and dissertations which contain embedded Published Journal Articles as part of the formal submission may be hosted publicly by the awarding institution with a link to the formal publication through the relevant DOI. Any other sharing of Published Journal Articles is by agreement with the publisher only.

Signed: ______________________________________ Name printed: ___________________________________________

Title and Company (if employer representative): _______________________Date: __________________________________